Other Components

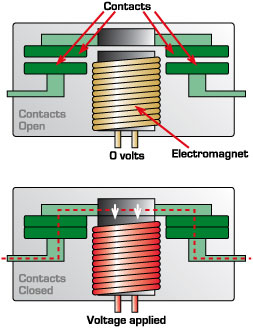

ContactorsA contactor is basically an electronically controlled switch, designed to carry a large amount of power. For those familiar with electronic relays, it's the same principle on a larger scale. They consist of an coil (electromagnet) which is energised from a low voltage (typically 12V for EV use). When energised, the coil pulls contacts closed allowing current to flow through the device. In EVs, they are used to isolate the battery pack when the key is turned off - the equivalent of ignition in an ICE vehicle. For typical EVs, contactors rated to around 200 amps continuous are recommended. Contactors up to 600 amps continuous are available for high-performance EV applications. |

|

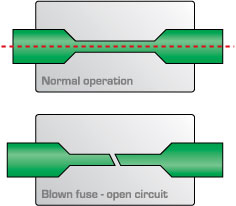

FusesMost people are familiar with the function of fuses, and their use in EVs is no different - to protect the electronics from overloads and short circuits. Internally they have a conductive section which will break if a certain electrical current threshold is exceeded, stopping the flow. For safety reasons, it is recommended that each group of batteries in an EV includes a fuse very close to the positive terminal. |

|

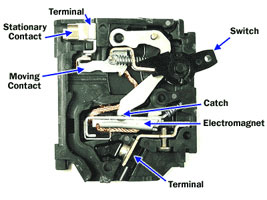

Circuit BreakersCircuit breakers perform a similar function to fuses - protecting the electronics from overload and short circuit - with the added advantage that they are resettable. Circuit breakers can also be tripped manually using a switch. Circuit breakers are more expensive than fuses but are a good investment in the long run. For typical EV projects, circuit breakers around 200 amps continuous are recommended. |

|

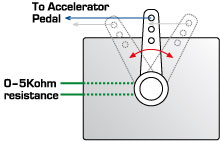

Pot BoxesPetrol vehicles use a cable between the accelerator pedal and the engine's throttle. In EVs, the throttle end is replaced with a connection to a pot box, which is basically an electronic throttle connected to your motor speed controller. Most pot boxes are simply an industrial variable resistor (5Kohm is the standard) in a robust packaging. Some newer motor speed controllers are using digital pot boxes with optical encoders, which tend to be more reliable. |

|

DC-DC ConvertersMost vehicles (electric or petrol powered) have a variety of electronic systems which run on 12 volts - such as lights, stereo, electric windows, alarm, etc. Petrol vehicles use an alternator running off the engine to power these systems. Electric vehicles typically use a DC-DC converter, which just converts the high battery voltage into a 12 volt DC output for these auxilliary systems. Typically, the DC-DC converter will be rated to about 300-500 watts, although this does vary greatly depending on requirements. As with petrol vehicles, a conventional 12V lead acid car battery is typically used in conjunction with and charged by the DC-DC converter. |

|

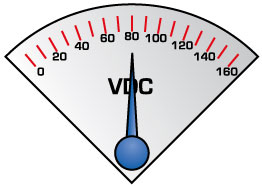

InstrumentationThe main two gauges you will need to add for an EV are a voltmeter to monitor your battery pack voltage, and an ammeter which measures either the current coming out of the battery pack or the current flowing through the motor. Instead of a fuel gauge, some EVs also have a "state of charge" meter. These usually include some clever electronics to calculate the amount of power which has come out of the battery, and from this work out how much of your battery capacity you have left. Some will even act like a trip computer, telling you how much range you have remaining. Vehicles with a good battery management system may also have a display showing the voltage levels of all batteries in the pack. This is a great way to monitor the health of individual cells, and to make sure none get over-discharged. |

|